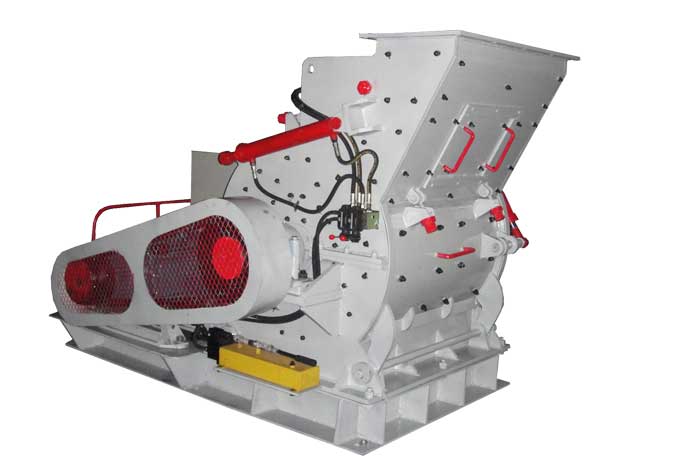

Jaw Crusher

Max Feeding Size: 125-1200mmCapacity: 1 - 1100(Ton/H)

Category: Primary crusher, secondary crusher

Price: Inquiry

Jaw crushers are typically used as primary crushers, or the first step in the process of reducing rock. They typically crush using compression. The rock is dropped between two rigid pieces of metal, one of which then move inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece.

Liming offers a wide range of sizes of primary and secondary jaw crushers. They incorporate steeply aligned toggle seats for efficient nip angles and high production rates. The primary models offer hydraulically adjusted wedges for quick and easy adjustments to closed side settings. All sizes incorporate a fixed jaw die configuration with a wrap-around design that protects the crusher frame. Easy-to-maintain cheek plate bolt system. Crushers are driven by extra large, overhead eccentric shafts seated in closely-spaced spherical, self-aligning roller bearings. Comparisons with other brands will show that Liming crushers are among the most heavy-duty machines available. Important features to consider are: bearing size, shaft size, machine weight.

Applications of Jaw Crusher

- Crushed or broken concrete

- Primary and secondary hard rock crushing

- High production capacity with low cost per ton

- Primary crushing equipment in a crushing circuit

Features andy benefits of jaw Crusher of liming

- Pitched fixed jaw dies and steeply aligned toggle seats. Most efficient nip angles. Highly-effective geometry

- Fixed jaw dies with wrap-around design protects the frame and eliminates the need for additional wedges

- Hydraulically adjusted wedges for quick adjustments to the closed setting when new products are needed or as the jaw dies wear

- Side tensioning wedges to keep dies in correct operating position

- Advanced cheek plate bolt system for easy maintenance

- Extra large, drop-forged, heat-treated overhead eccentric shafts

- Lower maintenance & operating costs

- Improved service life of critical components

- Advanced materials & processes

| Model | Max. Feeding Size (mm) | Adjustable Discharge opening (mm) | Capacity (t/h) | Motor Power (kW) | Overall Dimensions (mm) | Weight (t) |

| PE250×400 | 200 | 20-60 | 5-20 | 15 | 1150×1275×1240 | 2.8 |

| PE250x1000 | 210 | 15-50 | 15-50 | 30 | 2790x2670x1380 | 6.5 |

| PE400×600 | 350 | 40-100 | 15-60 | 30 | 1700×1732×1653 | 6.5 |

| PE500×750 | 425 | 50-100 | 50-100 | 55 | 2035×1921×2000 | 10.3 |

| PE600×900 | 500 | 65-160 | 60-130 | 75 | 2290×2206×2370 | 15.5 |

| PE750×1060 | 630 | 80-140 | 110-250 | 110 | 2620×2302×3110 | 26.7 |

| PE900×1200 | 750 | 100-200 | 160-380 | 130 | 3789×2826×3025 | 51 |

| PE1000×1200 | 850 | 200-300 | 315-550 | 130 | 3889×2826×3025 | 56 |

| PE1200×1500 | 1020 | 150-350 | 400-800 | 200 | 4200×3750×3820 | 88 |

Tags: Jaw CrusherStone CrusherCrusherRock Crusher

Our customer service support for English, if you hava any question please Contact Us.

Get More Information

(If you do not want to contact us online, please fill out the following table, we will contact you as soon as possible. We will strictly protect your privacy.)