T130X Superfine Grinding Mill

Max Feeding Size: ≤30mmCapacity: 4-13T/h

Category: Roller mill,Vertical mill,Mill for Micro Powder

Price: Inquiry

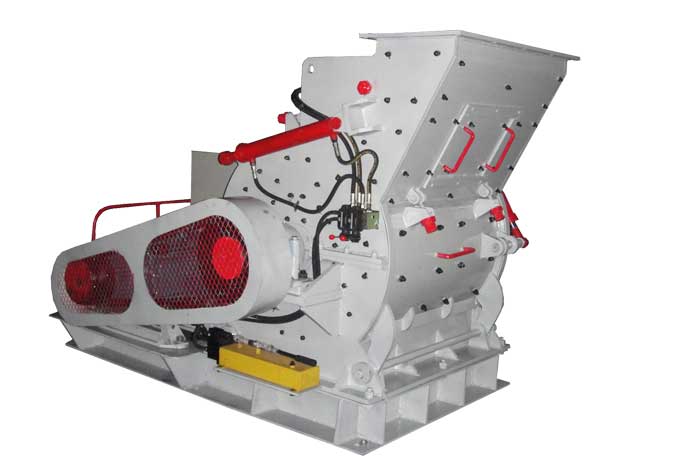

T130X superfine grinding mill with innovative design is a new-type grinding machine evolving from the original patented product - TGM Super Pressure Trapezium Mill based on market research, feedbacks and suggestions of customers both at home and abroad. The complete set of T130X grinding mill consists of mainframe, reducer, classifier, maintenance platform, blower, collector, electric controller, etc.And some auxiliary equipments such as jaw crusher, bucket elevator, electromagnetic vibration feeder and hopper, etc.

Working Principal:

Large materials are crushed by jaw crusher into required size for mainframe, then the crushed materials are elevated to the hopper by bucket elevator,then to the grinding chamber for grinding by vibrating feeder evenly and continuously. The powder goes upwards with the airflow, after separating by the classifier, those which can meet the fineness requirement enters into the collector through pipes for separating and collecting, and discharged from the discharged valve as finished products. The airflow is sucked into blower through wind recycling pipe at the upper part of cyclone power collector. And the closed airflow circulation system with negative pressure ensures the environmental health of production line site.

Features

- The body connected to the base of all soft contact without rigid contact. This avoid body vibration to analyzer, improved the accuracy of the analysis.

- Use of Germany Flender reducer It fully exploited the technical advantages of professional manufacturer to improve the stability of the machine. Reducer and motor is driven by the triangle belt for transmission for overload protection.

- The base made of high strength ductile cast iron Ductile cast iron has the performance of damping force of molten steel, and good impact resistance.

- The coupling of the elastic sleeve is used in the main unit and the gearbox, which avoided the phenomenon of easily breaking nylon pin, thus improving the reliability of equipment.

- Use of dust bypass collector The dust bypass collector has an insulation cavity to reduce dusty gas escape from the lower vents. Compare with other dust collector, the bypass dust collector are high-efficiency and less pressure loss, particularly for collecting dust particles that is difficult to collect by the general collectors.

- Establishing maintenance platform to make the mill maintenance more convenient and secure.

| Item | Unit | Specifications &Technical data |

| Quantity of roller | pcs | 4 |

| Diameter of roller x Height | mm | Ф410×210 |

| Diameter of ring x Height | mm | Ф1300×210 |

| Rotation speed | rmp | 103 |

| Max. feeding size | mm | <30 |

| Output size | mm | 0.074—0.038 |

| Capacity | t/h | 4-13 |

| Weight | t | 18 |

| Name | Item | Unit | Specifications& Technical data |

| Motor for mainframe | Model | Y280S-4 | |

| Power | kw | 75 | |

| Rotating speed | rpm | 1480 | |

| Adjustable speed motor for classifier | Model | Y160L-4 | |

| Power | kw | 15 | |

| Rotating speed | rpm | 1460 | |

| Motor for elevator | Model | Y100L2-4 | |

| Power | kw | 3 | |

| Rotating speed | rpm | 1430 | |

| Motor for blower | Model | Y280M-4 | |

| Power | kw | 90 | |

| Rotating speed | rpm | 1480 | |

| Motor for Jaw Crusher | Jaw crusher Model | PE 250×400 | |

| Model | Y180L-6 | ||

| Power | kw | 15 | |

| Rotating speed | rpm | 970 | |

| Electromagnetic vibration feeder | Model | GZ3F | |

| Power | W | 200 |

Tags: Grinding machineMill for Powder

Our customer service support for English, if you hava any question please Contact Us.

Get More Information

(If you do not want to contact us online, please fill out the following table, we will contact you as soon as possible. We will strictly protect your privacy.)