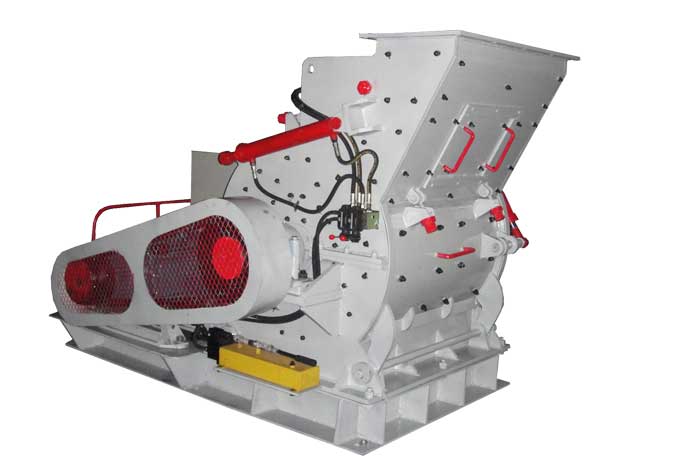

MTW Series Trapezium Mill

Max Feeding Size: 30-40mmCapacity: 3.5 - 25(Ton/H)

Category: Grinding Machine,Trapezium Mill,Vertical mill

Price: Inquiry

MTW Series Trapezium Mill is a kind of Vertical Roller mill, It is the latest grinding equipment, with its own knowledge patents, have reached modern advanced level in the world. This series mill absorbing the European advanced technology and many engineers' ripe experience, combining the actual requirement and proposal of our 9518 customers', have been developed on the basis of our professional engineers' hard researching. This new type mill adopts bevel gear overall drive, inner automatic Thin-Oil lubricating system, arc air channel and several latest patent technology. The Conventional configuration of MTW Sequence Mill consists of Principal Device, powder classifier, blower, elevator, feeder, hopper, cyclone collector, Dirt catcher, blower, Engine, pipe, Electrical Manage box and so on.

Working Principle

Very first, raw material Need to be crushed by the jaw crusher or other crusher to the Dimension specified, and then the crushed stuff is elevated into a hopper from which the stuff is loaded, Via the vibrating feeder, evenly and Continually into the grinding chamber for Energy-Digesting. Right after this, the Soil stuff is carried by the Oxygen into the separator for screening. The Good powder are blow into the cyclone collector and are poured out Via the output-powder valve as the Last Products and services and the Hard stuff after the screening will be recycled Back again into the grinding chamber for regrinding. The Established's Oxygenflow Method is closely sealed up and circulated Below Problem of Undesirable Stress.

Features of MTW Series Trapezium Mill

- Adopt insolating structure between the inner core and mixed air flow that Enhance the classifying Effectiveness and Accuracy.

- non-resistance inlet shell: Conventional observation door of shell protrude that makes the inner surface is not so smooth which brings eddy effect and increase the consumption. MTW series mill adopts the same curved surface which avoids the eddy effect.

- bevel gear integral transmission: The traditional mill needs decelerator and ratcheting to drive the main shaft that increase the centering difficulty and is easy to bring noise as well as reduce the efficiency. MTW series mills adopt bevel gear integral transmission that compact the whole structure and simplify the installation as well as improve the efficiency.

- Inner light-oil lubrication system: The traditional mills’ lubrication adopts grease lubrication which increases the resistance of lubrication, creates high inherent temperature and shortens the service life of bearing. MTW series mills adopt light-oil lubrication achieve the lubrication of bearing without oil pump and lubrication station

- Curved surface shovel with changeable edge: The traditional mills adopt quick wear edge and edge combine with shovel. If the edge is worn, all of the shovel should be changed that increase the cost and the stop time. The edge of MTW series mill adopts wearable alloy materials which improve the service life. The Changeable edge is easy to change that save time and cost. The traditional flat shovel make the materials accumulate in one level that reduces the ring and roller’ service life. The curved surface shovel makes a vertical material liner which increases the working face and capacity.

- Fine appearance: MTW series mills not only adopt many advanced structure but also optimize the appearance.

| Model Specification Name | MTW110 | MTW138 | MTW175 |

| Quantity of roller (PCS) | 4 | 4 | 5 |

| Inner diameter of ring (mm) | Ф1100 | Ф1380 | Ф1750 |

| Rotary speed of main frame(r/min) | 120 | 96 | 75 |

| Max. Feeding size(mm) | < 30 | < 35 | < 40 |

| Output size (mm) | 1.6~0.045 The fineness is 0.038 | 1.6~0.045 The fineness is 0.038 | 1.6~0.045 The fineness is 0.038 |

| capacity (t/h) | 3.5~10 | 6.5~15 | 11~25 |

| Overall dimension (mm) | 8910×6950×9010 | 9860×8340×10227 | 13500×11500×9500 |

| Total weight (t) | 18 | 28.5 | 46 |

| Name | Item | Unit | Specifications & Technical Data | ||

| MTW110 | MTW138 | MTW175 | |||

| Motor for main frame | Model | Y280M-6 | Y315M1-6 | Y355M2-8 | |

| Power | kW | 55 | 90 | 160 | |

| Rev. | rpm | 980 | 990 | 990 | |

| Motor for separator | Model | YCT200-4A(YCT200-4B) | YCT250-4A(YCT225-4A) | YCT225-4A(YCT250-4A) | |

| Power | kW | 7.5 | 18.5 | 30 | |

| Rev | rpm | 125~1250 | 125~1250 | 125~1250 | |

| Motor for Elevator | Model | TH250 | TH250 | TH315 | |

| Motor model | Y100L2-4 | Y100L2-4 | Y112M-4 | ||

| Power | kW | 3 | 3 | 4 | |

| Rev | rpm | 1420 | 1420 | 1420 | |

| Motor for Blower | Model | Y250M-4 | Y280M-4 | Y315L1-4 | |

| Power | kW | 55 | 110 | 200 | |

| REV | rpm | 1480 | 1480 | 1480 | |

| Motor for Jaw Crusher | Model | PE | 250×400 | 250×400 | 250×750 |

| Y180L-6 | Y180L-6 | Y200L2-6 | |||

| Power | KW | 15 | 15 | 22 | |

| REV | rpm | 970 | 970 | 970 | |

| Electro-Magnetic Vibrating Feeder | Model | GZ2F | GZ3F | GZ4F | |

| Power | W | 150 | 200 | 450 | |

Tags: Grinding machineMilling MachineTrapezium Mill

Our customer service support for English, if you hava any question please Contact Us.

Get More Information

(If you do not want to contact us online, please fill out the following table, we will contact you as soon as possible. We will strictly protect your privacy.)