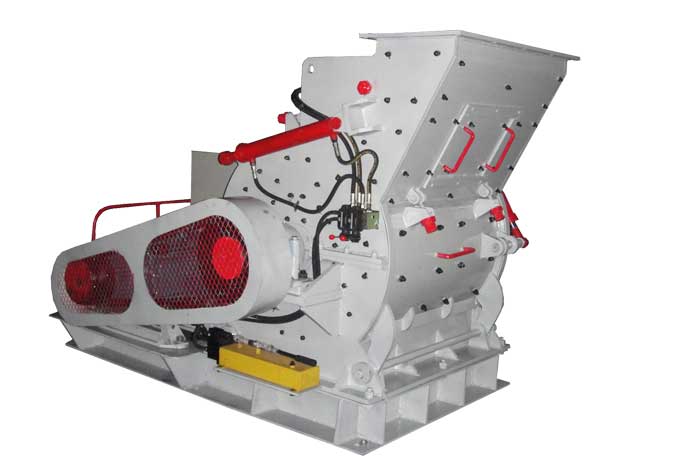

Ball Mill

Max Feeding Size: < 30mmCapacity: 0.65 - 35(Ton/H)

Category: Industrial Mill, Horizontal Mill,Grinding machine

Price: Inquiry

A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics.

The ball mill is a Important equipment to grind the crushed materials, and the ball mill is Broadly Applied in powder-Generating Manufacturing Collection Which includes cement, silicate, new-Sort Developing Product, refractory Product, fertilizer, ore dressing of ferrous Material and non-ferrous Material, Wineglass ceramics, And so on, and the ball mill can grind Diverse ores and other Supplies with Dried out Sort and wet Sort. There are two Varieties of ball mill, grate Sort and overfall Sort Because of to Several Methods of discharging Product.

Working principle of Ball mill

Ball mill is a skeleton pattern ball mill with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.

Application of Ball mill

1. Ball mill in limestone grinding

Ball mill can grind limestone into powder. Limestone Normally Consists of variable Quantities of silica in the Type of chert or siliceous skeletal fragment, as Nicely as Various Quantities of clay, silt and sand sized terrestrial detritus carried in by rivers. Limestone powder can be used as filler in cpainting industry to enhance the performance of quality paints.

2. Ball mill in cement grinding

Cement grinding is the final process in cement manufacturing, which cost the most electric power. Its main function is to grind cement clinkers into the required size. Ball mill can be used in this process.

3. Ball mill in marble grinding

Ball mill can be Utilized to grind marble. Marble is a metamorphic rock composed of recrystallized carbonate Mineral deposits, most Generally calcite or dolomite. Marble is Generally Utilized for sculpture and as a Constructing Materials. Finely Soil marble powder is a Element in Cardstock, and in Customer Programs This kind of as toothpaste, plastics, and paints.

4. Ball mill in bentonite grinding

Bentonite is an absorbent aluminum silicate clay Created from volcanic ash and Utilized in Numerous adhesives, cements, and ceramic fillers. The output Dimension from Raymond mill varies from 440 to 613 microns (0.44 ~0.613mm or 425~100 mesh). These Last Programs Dimensions can Encounter the demands from Diverse Customers Via the Blended Impact of the separator and the blower.

| Model | Speed of bucket (r/min) | Weight of ball (t) | Size of feed opening (mm) | size of outputting feed (mm) | Production (t/h) | Power (kW) | Weight (t) |

| Ф900×1800 | 42 | 1.4 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 3.6 |

| Ф900×3000 | 41 | 2.5 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.5 |

| Ф1200×2400 | 36 | 3.5 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 11.5 |

| Ф1200×3000 | 32 | 5 | ≤25 | 0.075-0.4 | 1.6-5 | 45 | 12.8 |

| Ф1200×4500 | 32 | 5.5 | ≤25 | 0.075-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ф1500×3000 | 31 | 6.8 | ≤25 | 0.075-0.4 | 2-7 | 75 | 17 |

| Ф1500×4500 | 27 | 10.5 | ≤25 | 0.075-0.4 | 3.5--8 | 110 | 21 |

| Ф1500×5700 | 27 | 15 | ≤25 | 0.075-0.4 | 3.5-10 | 132 | 24.7 |

| Ф1830×3000 | 26 | 13 | ≤25 | 0.075-0.4 | 4-12 | 160 | 28 |

| Ф1830×6400 | 26 | 23 | ≤25 | 0.075-0.4 | 6.5-15 | 210 | 34 |

| Ф1830×7000 | 26 | 25 | ≤25 | 0.075-0.4 | 6.5-22 | 210 | 36 |

| Ф2200×5500 | 21 | 30 | ≤25 | 0.075-0.4 | 10-22 | 370 | 48.5 |

| Ф2200×6500 | 21 | 30 | ≤25 | 0.075-0.4 | 14-50 | 380 | 52.8 |

| Ф2200×7500 | 21 | 33 | ≤25 | 0.075-0.4 | 16-50 | 380 | 56 |

| Φ2200×9500 | 21 | 38 | ≤25 | 0.074-0.4 | 18-60 | 475 | 62 |

Tags: Grinding machineBall millGrinding millCement mill

Our customer service support for English, if you hava any question please Contact Us.

Get More Information

(If you do not want to contact us online, please fill out the following table, we will contact you as soon as possible. We will strictly protect your privacy.)